В геологических и минералогических исследованиях лабораторная трубчатая печь служит миниатюрным, контролируемым аналогом земной коры и мантии. Она позволяет ученым точно моделировать экстремальные температурные и атмосферные условия, существующие в недрах планеты, давая возможность изучать, как породы и минералы плавятся, трансформируются и перекристаллизуются в течение геологических времен в контролируемых лабораторных условиях.

Лабораторная трубчатая печь — это не просто нагревательное устройство; это критически важный инструмент для экспериментальной петрологии и минералогии. Она позволяет исследователям выйти за рамки наблюдения за существующими породами и активно воссоздавать динамические высокотемпературные процессы, которые их формируют.

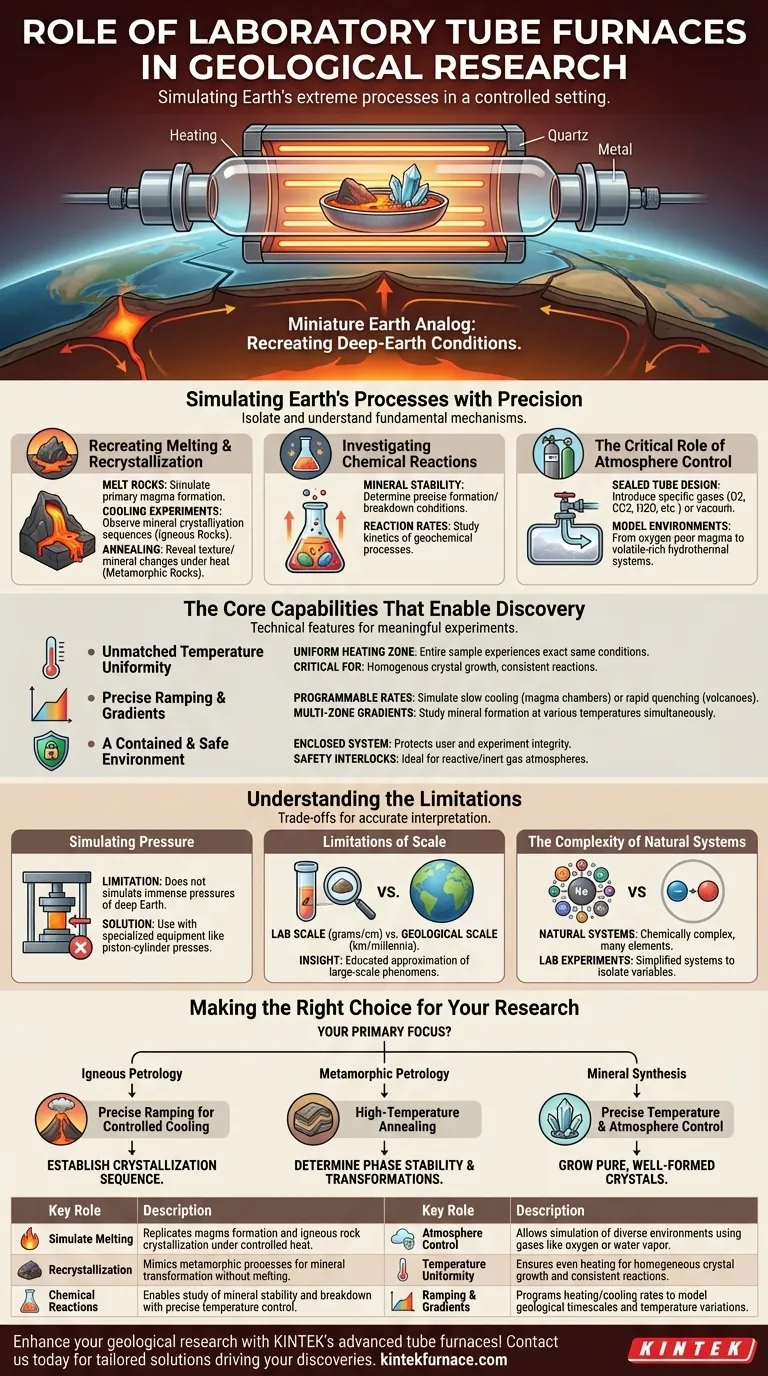

Точное моделирование земных процессов

Основная роль трубчатой печи в геологии заключается в воспроизведении условий, которые невозможно наблюдать напрямую. Контролируя ключевые переменные, исследователи могут изолировать и понять фундаментальные механизмы образования пород и минералов.

Воссоздание плавления и перекристаллизации

Трубчатые печи обеспечивают высокий, равномерный нагрев, необходимый для плавления образцов горных пород и минералов. Это позволяет геологам изучать состав первичных магм и наблюдать, как различные минералы кристаллизуются из расплава по мере его охлаждения, имитируя образование магматических пород.

Аналогичным образом, они могут подвергать существующие минералы интенсивному нагреву без плавления для моделирования метаморфических процессов. Это помогает выявить, как текстуры пород и минеральные ассоциации изменяются под воздействием захоронения и тектонической активности.

Исследование химических реакций

Стабильность минералов и химические реакции сильно зависят от температуры. Трубчатая печь обеспечивает точный контроль температуры, необходимый для определения точных условий, при которых определенный минерал будет образовываться, распадаться или вступать в реакцию с окружающей средой.

Критическая роль контроля атмосферы

Герметичная конструкция трубы имеет решающее значение. Она позволяет исследователям вводить специфические газы (или создавать вакуум) для моделирования разнообразных атмосферных условий, встречающихся внутри Земли.

Контролируя наличие таких газов, как кислород, углекислый газ или водяной пар, ученые могут точно моделировать среды, начиная от бедных кислородом магматических камер и заканчивая богатыми летучими компонентами гидротермальными системами, что существенно влияет на то, какие минералы образуются.

Основные возможности, обеспечивающие открытия

Трубчатая печь уникально подходит для геологических исследований благодаря своим основным конструктивным особенностям. Эти технические возможности дают исследователям необходимый контроль для проведения значимых экспериментов.

Непревзойденная равномерность температуры

Ключевым преимуществом является способность поддерживать высокооднородную температурную зону по всей длине технологической трубы. Это гарантирует, что весь образец подвергается воздействию абсолютно одинаковых условий, что критически важно для выращивания гомогенных кристаллов или обеспечения равномерного протекания реакции.

Точное изменение режимов и градиенты

Современные контроллеры позволяют геологам программировать определенные скорости нагрева и охлаждения (рампинг). Это может имитировать медленное охлаждение глубокой магматической камеры или быстрое закаливание при вулканическом извержении.

Некоторые многозонные печи также могут создавать стабильный температурный градиент, позволяя исследователям изучать, как различные минералы одновременно образуются при разных температурах из одного и того же исходного материала.

Закрытая и безопасная среда

Закрытая конструкция трубчатой печи обеспечивает безопасную, изолированную среду для высокотемпературных экспериментов. Защитные блокировки и надежная изоляция защищают как пользователя, так и целостность эксперимента, особенно при работе с реакционноспособными или инертными газовыми средами.

Понимание ограничений

Несмотря на свою мощность, трубчатая печь является инструментом моделирования с присущими ей компромиссами, которые важно учитывать для точной научной интерпретации.

Моделирование давления

Стандартная трубчатая печь отлично справляется с контролем температуры и атмосферы, но не моделирует давление. Огромное давление, существующее в недрах Земли, существенно влияет на стабильность минералов. Для исследований, требующих как высокой температуры, так и высокого давления, трубчатые печи часто используются в сочетании с другим специализированным оборудованием, таким как прессы типа поршень-цилиндр.

Ограничения масштаба

Лабораторные эксперименты проводятся в масштабах граммов и сантиметров, в то время как геологические процессы происходят в масштабах километров и тысячелетий. Полученные результаты дают важнейшее представление об основных физических и химических процессах, но являются обоснованной аппроксимацией крупномасштабных природных явлений.

Сложность природных систем

Природные магмы и геологические системы химически сложны и часто содержат десятки элементов. Лабораторные эксперименты обычно упрощают эти системы для выделения переменных. Это является научной силой для понимания конкретных механизмов, но ограничением при применении результатов к сложной природной среде.

Как сделать правильный выбор для ваших исследований

Чтобы эффективно использовать трубчатую печь, соотнесите ее возможности с вашим конкретным геологическим вопросом.

- Если ваш основной фокус — магматическая петрология: Используйте точное изменение режимов температуры печи для контролируемых экспериментов по охлаждению, чтобы установить последовательность кристаллизации минералов из расплава.

- Если ваш основной фокус — метаморфическая петрология: Используйте печь для высокотемпературного отжига, чтобы определить фазовую устойчивость и точки преобразования ключевых индексных минералов.

- Если ваш основной фокус — синтез минералов: Используйте комбинацию точного контроля температуры и атмосферы для выращивания чистых, хорошо сформированных кристаллов минералов для последующего анализа или характеризации.

В конечном счете, лабораторная трубчатая печь является незаменимым инструментом, который позволяет геологам проверять гипотезы и раскрывать скрытые формирующие процессы планеты, эксперимент за экспериментом.

Сводная таблица:

| Ключевая роль | Описание |

|---|---|

| Моделирование плавления | Воспроизводит образование магмы и кристаллизацию магматических пород при контролируемом нагреве. |

| Перекристаллизация | Имитирует метаморфические процессы для трансформации минералов без плавления. |

| Химические реакции | Позволяет изучать стабильность и распад минералов при точном контроле температуры. |

| Контроль атмосферы | Позволяет моделировать разнообразные среды с использованием газов, таких как кислород или водяной пар. |

| Равномерность температуры | Обеспечивает равномерный нагрев для гомогенного роста кристаллов и последовательных реакций. |

| Изменение режимов и градиенты | Программирует скорости нагрева/охлаждения для моделирования геологических временных шкал и температурных вариаций. |

Улучшите свои геологические исследования с передовыми трубчатыми печами KINTEK! Используя исключительные возможности НИОКР и собственное производство, мы предоставляем различным лабораториям высокотемпературные решения, такие как трубчатые печи, муфельные печи и системы CVD/PECVD. Наша глубокая возможность индивидуализации обеспечивает точное соответствие вашим уникальным экспериментальным потребностям, от магматической петрологии до синтеза минералов. Свяжитесь с нами сегодня, чтобы узнать, как наши индивидуальные печные решения могут способствовать вашим открытиям!

Визуальное руководство

Связанные товары

- 1700℃ Высокотемпературная лабораторная трубчатая печь с кварцевой или глиноземной трубкой

- 1400℃ высокотемпературная лабораторная трубчатая печь с кварцевой и глиноземной трубкой

- Лабораторная вакуумная трубчатая печь высокого давления Кварцевая трубчатая печь

- Многозональная лабораторная кварцевая трубчатая печь трубчатая печь

- Печь с регулируемой инертной азотной атмосферой 1700℃

Люди также спрашивают

- Как высокотемпературная трубчатая печь используется в синтезе нанокомпозитов MoO2/MWCNT? Руководство по точности

- Какие последние улучшения были внесены в лабораторные трубчатые печи? Раскройте точность, автоматизацию и безопасность

- Как вертикальная трубчатая печь обеспечивает точный контроль температуры? Раскройте превосходную температурную стабильность для вашей лаборатории

- Как вертикальные трубчатые печи соответствуют экологическим стандартам? Руководство по чистоте и эффективности работы

- Какие функции безопасности и надежности встроены в вертикальную трубчатую печь? Обеспечение безопасной, стабильной высокотемпературной обработки