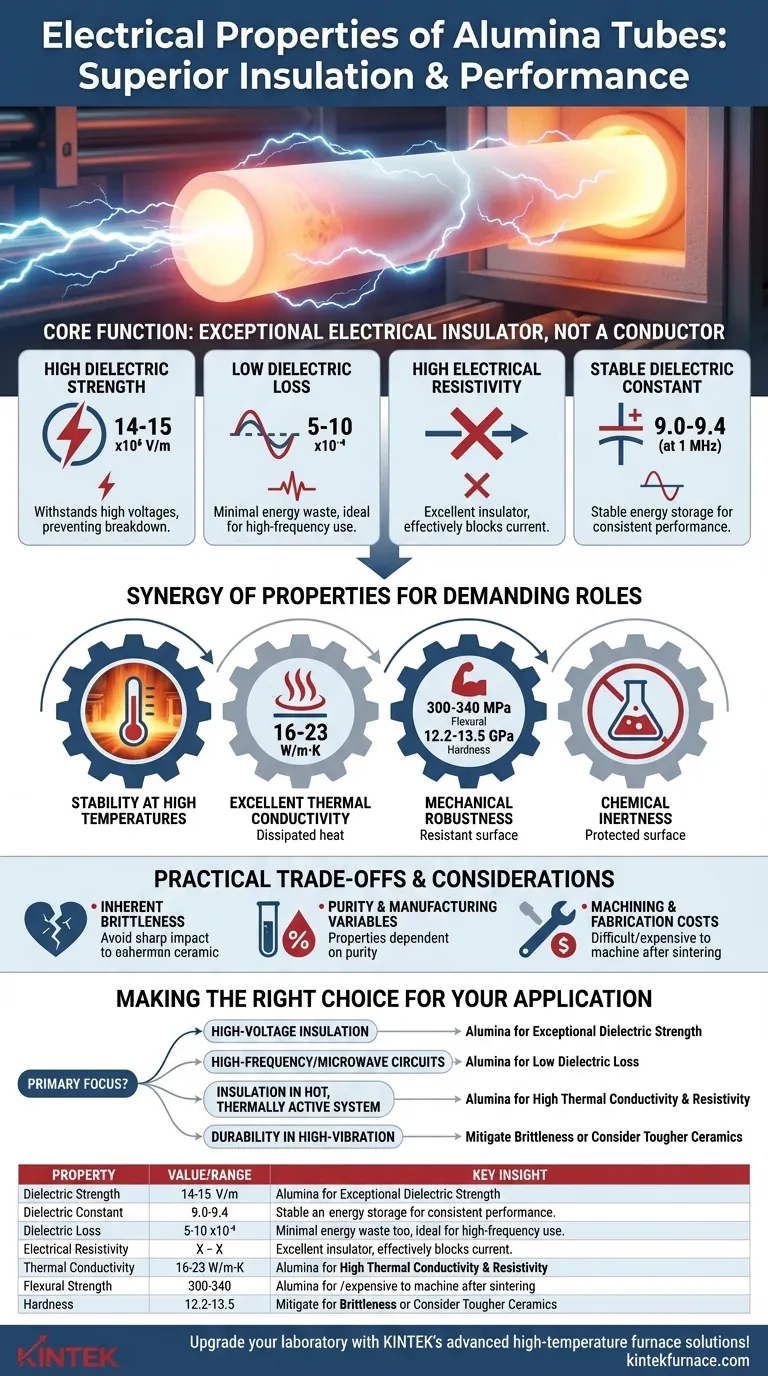

Alumina tubes are widely used in high-temperature and electrical applications due to their excellent electrical and thermal properties. Their key electrical properties include a dielectric constant of 9.0–9.4 at 1 MHz, a low dielectric loss angle (5–10 × 10⁻⁴), and a high dielectric strength (14–15 × 10⁶ V/m). These properties make them ideal for insulating components in high-voltage and high-frequency environments, such as in atmosphere retort furnaces. Additionally, their mechanical strength, thermal stability, and resistance to wear and corrosion further enhance their suitability for demanding industrial and laboratory applications.

Key Points Explained:

-

Dielectric Properties

- Dielectric Constant (9.0–9.4 at 1 MHz):

This moderate dielectric constant allows alumina tubes to effectively store and dissipate electrical energy, making them useful in capacitors and insulating components. - Dielectric Loss Angle (5–10 × 10⁻⁴):

The low loss angle indicates minimal energy dissipation as heat, which is crucial for high-frequency applications like RF components and microwave devices. - Dielectric Strength (14–15 × 10⁶ V/m):

This high breakdown voltage ensures reliability in high-voltage environments, such as electrical insulators and power transmission components.

- Dielectric Constant (9.0–9.4 at 1 MHz):

-

Thermal Stability & Electrical Performance

- Alumina tubes maintain their electrical properties even at extreme temperatures (up to 1800°C), ensuring consistent performance in high-heat environments like atmosphere retort furnaces.

- Their low thermal expansion (7.2–7.3 × 10⁻⁶ mm/°C) and high thermal conductivity (16–23 W/(m·K)) prevent mechanical stress and thermal runaway in electrical systems.

-

Mechanical & Chemical Advantages

- High compression resistance and thermal shock resistance make alumina tubes durable in fluctuating temperatures.

- Corrosion and wear resistance extend their lifespan in harsh industrial settings, such as float glass or bioceramics production.

-

Applications in Electrical Systems

- Used in insulators, thermocouple sheaths, and high-temperature sensors due to their gas-tight and vacuum-compatible properties.

- Suitable for laboratory analysis equipment where precision and stability are critical.

-

Customizability & Maintenance

- Available in custom sizes and profiles to fit specific industrial needs.

- Requires ultrasonic cleaning to maintain surface integrity and electrical performance over time.

Have you considered how alumina’s combination of electrical and thermal properties could optimize your high-temperature processes? These tubes are not just passive components but enablers of technologies that quietly shape modern healthcare, manufacturing, and energy systems.

Summary Table:

| Property | Value | Significance |

|---|---|---|

| Dielectric Constant | 9.0–9.4 at 1 MHz | Enables effective energy storage and dissipation in capacitors and insulators. |

| Dielectric Loss Angle | 5–10 × 10⁻⁴ | Minimizes energy loss as heat, ideal for RF and microwave applications. |

| Dielectric Strength | 14–15 × 10⁶ V/m | Ensures reliability in high-voltage environments like power transmission. |

| Thermal Stability | Up to 1800°C | Maintains electrical performance in extreme heat (e.g., retort furnaces). |

| Thermal Conductivity | 16–23 W/(m·K) | Prevents thermal runaway and mechanical stress in electrical systems. |

Enhance your lab or industrial processes with alumina tubes tailored to your needs!

At KINTEK, we combine cutting-edge R&D with in-house manufacturing to deliver advanced high-temperature solutions. Our alumina tubes are designed for precision, durability, and performance in demanding environments—from vacuum systems to high-voltage insulation.

Contact us today to discuss custom solutions or explore our range of high-performance laboratory and industrial equipment. Let’s optimize your applications together!

Products You Might Be Looking For:

High-vacuum observation windows for precision monitoring

Robust sapphire glass sight windows for ultra-high vacuum systems

Reliable stainless steel ball stop valves for vacuum control

Vacuum flange blind plates for system integrity

Precision electrode feedthroughs for high-voltage applications

Визуальное руководство

Связанные товары

- 1400℃ высокотемпературная лабораторная трубчатая печь с кварцевой и глиноземной трубкой

- Лабораторная вакуумная трубчатая печь высокого давления Кварцевая трубчатая печь

- Многозональная лабораторная кварцевая трубчатая печь трубчатая печь

- Вращающаяся трубчатая печь с несколькими зонами нагрева

- 2200 ℃ Графитовая вакуумная печь для термообработки

Люди также спрашивают

- Каковы требования к материалам для труб печей? Оптимизация производительности и безопасности в высокотемпературных лабораториях

- Как вертикальная трубчатая печь способствует моделированию промышленного процесса спекания железных руд?

- Какие функции безопасности и надежности встроены в вертикальную трубчатую печь? Обеспечение безопасной, стабильной высокотемпературной обработки

- Как вертикальная трубчатая печь используется для изучения воспламенения топливной пыли? Моделирование промышленного сгорания с высокой точностью

- В чем разница между роликовыми печами и трубчатыми печами в использовании трубок из оксида алюминия? Сравните транспортировку и удержание (герметизацию)